Important: The GCConnex decommission will not affect GCCollab or GCWiki. Thank you and happy collaborating!

Difference between revisions of "AI-Assisted Quality Control of CTD Data"

| Line 1: | Line 1: | ||

| − | + | As part of the suite of Conductivity, Temperature, Depth (CTD) AI tools being produced by the Office of the Chief Data Steward (OCDS), we are developing a model to assist with identifying and deleting poor quality scans during the CTD quality control process. Using a combination of a Gaussian Mixture Model (GMM) to cluster CTD scans into groups with similar physical properties and Multi-Layer Perceptrons to classify the scans in each group, we are able to automatically flags the poor-quality scans to be deleted with a high degree of accuracy. Through the deployment of the model as a real-time online endpoint and the support of model communication through a client-side program, we have successfully integrated an experimental model into the client's business process in a field testing environment. The continuation of this line of work will now look to bring the model into a production environment for regular usage in the quality control process. | |

| − | |||

== Use Case Objectives == | == Use Case Objectives == | ||

Revision as of 10:28, 22 December 2022

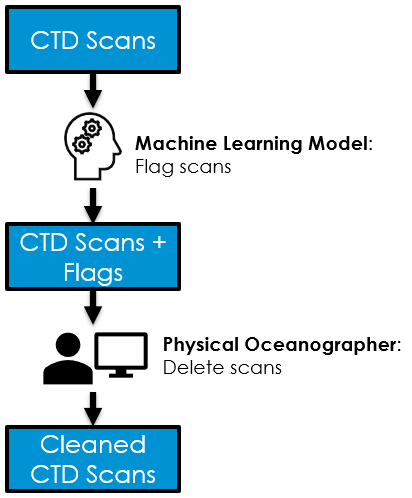

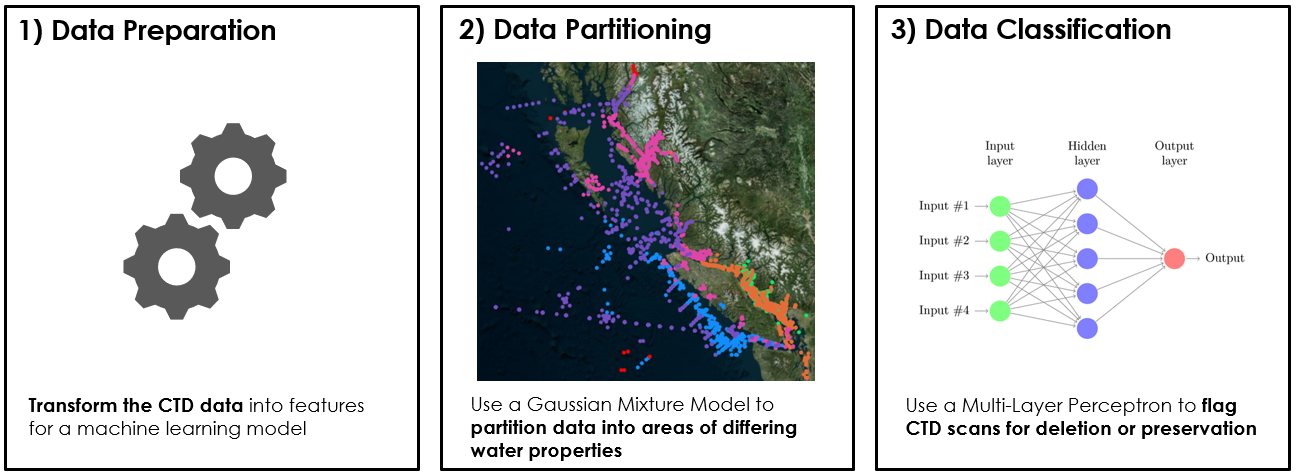

As part of the suite of Conductivity, Temperature, Depth (CTD) AI tools being produced by the Office of the Chief Data Steward (OCDS), we are developing a model to assist with identifying and deleting poor quality scans during the CTD quality control process. Using a combination of a Gaussian Mixture Model (GMM) to cluster CTD scans into groups with similar physical properties and Multi-Layer Perceptrons to classify the scans in each group, we are able to automatically flags the poor-quality scans to be deleted with a high degree of accuracy. Through the deployment of the model as a real-time online endpoint and the support of model communication through a client-side program, we have successfully integrated an experimental model into the client's business process in a field testing environment. The continuation of this line of work will now look to bring the model into a production environment for regular usage in the quality control process.

Use Case Objectives

- Machine Learning Task: Flag in advance the scans to be deleted during CTD quality control

- Business Value: Flagged scans allow the analyst to quickly focus attention on crucial areas, reducing the time and effort required to delete scans

- Measures of Success:

- Accuracy of model predictions

- Client feedback on quality control speed-ups

- Aspirational Goals:

- Mitigation of uncertainty in human decisions

- Semi or full automation of scan deletions

Machine Learning Pipeline

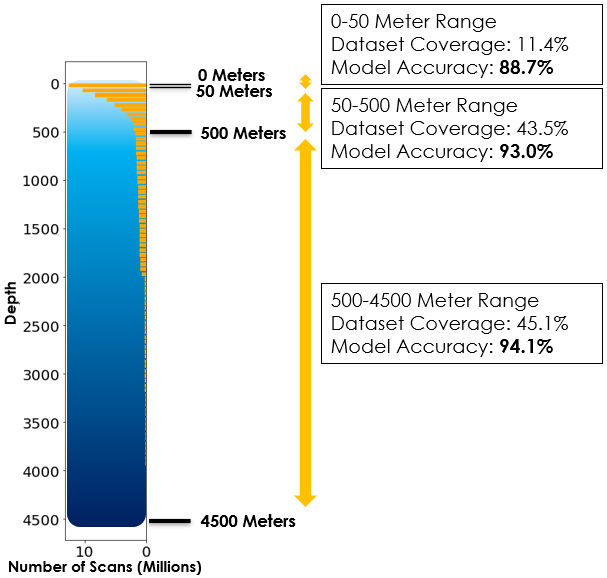

Experimental Model Performance

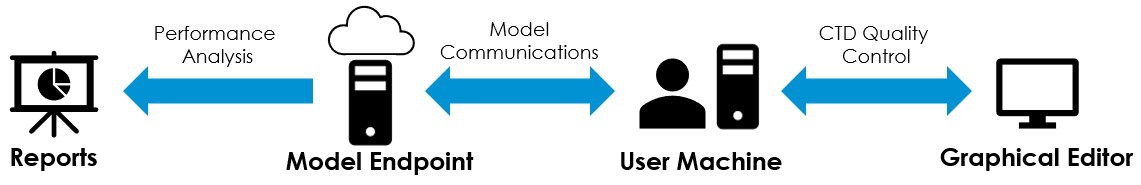

Model Deployment and Integration