Important: The GCConnex decommission will not affect GCCollab or GCWiki. Thank you and happy collaborating!

Difference between revisions of "AI-Assisted Quality Control of CTD Data"

| Line 2: | Line 2: | ||

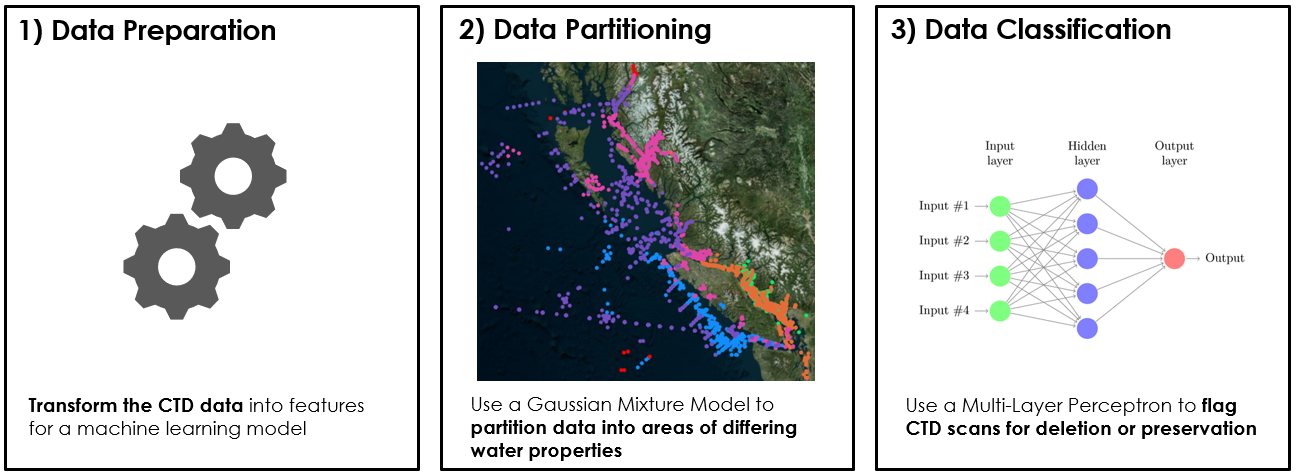

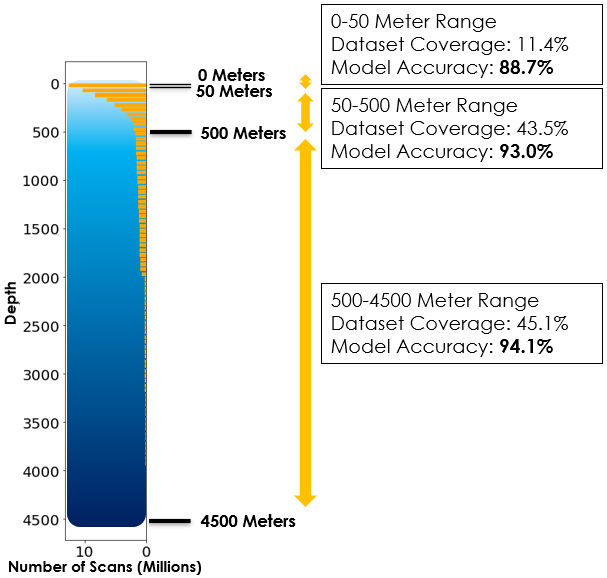

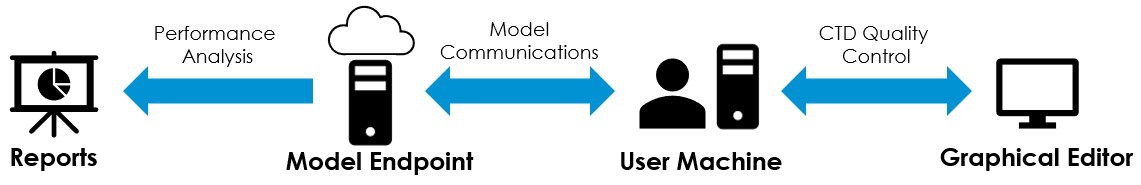

As part of the suite of Conductivity, Temperature, Depth (CTD) AI tools being produced by the Office of the Chief Data Steward (OCDS), we are developing a model to assist with identifying and deleting poor-quality scans during the CTD quality control process. Using a combination of a Gaussian Mixture Model (GMM) to cluster CTD scans into groups with similar physical properties and Multi-Layer Perceptrons to classify the scans in each group, we are able to automatically flag the poor-quality scans to be deleted with a high degree of accuracy. Through the deployment of the model as a real-time online endpoint and the support of model communication through a client-side program, we have successfully integrated an experimental model into the client's business process in a field testing environment. The continuation of this line of work will now look to bring the model into a production environment for regular usage in the quality control process. | As part of the suite of Conductivity, Temperature, Depth (CTD) AI tools being produced by the Office of the Chief Data Steward (OCDS), we are developing a model to assist with identifying and deleting poor-quality scans during the CTD quality control process. Using a combination of a Gaussian Mixture Model (GMM) to cluster CTD scans into groups with similar physical properties and Multi-Layer Perceptrons to classify the scans in each group, we are able to automatically flag the poor-quality scans to be deleted with a high degree of accuracy. Through the deployment of the model as a real-time online endpoint and the support of model communication through a client-side program, we have successfully integrated an experimental model into the client's business process in a field testing environment. The continuation of this line of work will now look to bring the model into a production environment for regular usage in the quality control process. | ||

== Use Case Objectives == | == Use Case Objectives == | ||

| − | [[File:Business_process.png|alt=|right| | + | [[File:Business_process.png|alt=|right|406x406px]] |

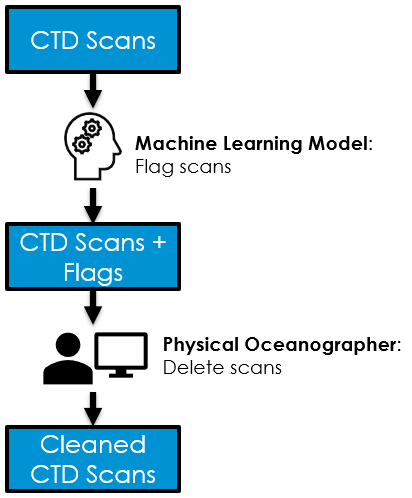

| − | The quality control process for CTD data is a highly time-intensive task. An oceanographer performs a visual inspection to identify poor-quality scans in each CTD profile using graphical editing software. As the task requires careful inspection and the CTD profiles collected during one year number in the thousands, this work consumes a large amount of time and effort. To ease this burden, we have produced an AI tool that is capable of flagging the poor-quality CTD scans such that these flags can be displayed to the oceanographer within the graphical editing software. This allows for the task to be sped up by providing a quick reference for the areas in the CTD profiles where attention is required. By providing flags for assisted decision-making rather than using the model for fully automated decision-making, we preserve the ability of oceanographer to use their domain expertise to make the best possible decisions. As the model becomes more mature and its performance improves, we may explore options to increase the degree of automation. | + | The quality control process for CTD data is a highly time-intensive task. An oceanographer performs a visual inspection to identify poor-quality scans in each CTD profile using graphical editing software. As the task requires careful inspection and the CTD profiles collected during one year number in the thousands, this work consumes a large amount of time and effort. To ease this burden, we have produced an AI tool that is capable of flagging the poor-quality CTD scans such that these flags can be displayed to the oceanographer within the graphical editing software. This allows for the task to be sped up by providing a quick reference for the areas in the CTD profiles where attention is required. By providing flags for assisted decision-making rather than using the model for fully automated decision-making, we preserve the ability of oceanographer to use their domain expertise to make the best possible decisions. As the model becomes more mature and its performance improves, we may explore options to increase the degree of automation. |

| − | |||

* '''Machine Learning Task''': Flag in advance the scans to be deleted during CTD quality control | * '''Machine Learning Task''': Flag in advance the scans to be deleted during CTD quality control | ||

| Line 18: | Line 17: | ||

==Machine Learning Pipeline== | ==Machine Learning Pipeline== | ||

| + | |||

| + | |||

[[File:Ml pipeline.png|Three-step process used in the machine learning pipeline.]] | [[File:Ml pipeline.png|Three-step process used in the machine learning pipeline.]] | ||

| + | |||

Revision as of 10:59, 22 December 2022

As part of the suite of Conductivity, Temperature, Depth (CTD) AI tools being produced by the Office of the Chief Data Steward (OCDS), we are developing a model to assist with identifying and deleting poor-quality scans during the CTD quality control process. Using a combination of a Gaussian Mixture Model (GMM) to cluster CTD scans into groups with similar physical properties and Multi-Layer Perceptrons to classify the scans in each group, we are able to automatically flag the poor-quality scans to be deleted with a high degree of accuracy. Through the deployment of the model as a real-time online endpoint and the support of model communication through a client-side program, we have successfully integrated an experimental model into the client's business process in a field testing environment. The continuation of this line of work will now look to bring the model into a production environment for regular usage in the quality control process.

Use Case Objectives

The quality control process for CTD data is a highly time-intensive task. An oceanographer performs a visual inspection to identify poor-quality scans in each CTD profile using graphical editing software. As the task requires careful inspection and the CTD profiles collected during one year number in the thousands, this work consumes a large amount of time and effort. To ease this burden, we have produced an AI tool that is capable of flagging the poor-quality CTD scans such that these flags can be displayed to the oceanographer within the graphical editing software. This allows for the task to be sped up by providing a quick reference for the areas in the CTD profiles where attention is required. By providing flags for assisted decision-making rather than using the model for fully automated decision-making, we preserve the ability of oceanographer to use their domain expertise to make the best possible decisions. As the model becomes more mature and its performance improves, we may explore options to increase the degree of automation.

- Machine Learning Task: Flag in advance the scans to be deleted during CTD quality control

- Business Value: Flagged scans allow the analyst to quickly focus attention on crucial areas, reducing the time and effort required to delete scans

- Measures of Success:

- Accuracy of model predictions

- Client feedback on quality control speed-ups

- Aspirational Goals:

- Mitigation of uncertainty in human decisions

- Semi or full automation of scan deletions

Machine Learning Pipeline

Experimental Model Performance

Model Deployment and Integration