Difference between revisions of "Project Drab"

Peter.yoon (talk | contribs) |

Peter.yoon (talk | contribs) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 20: | Line 20: | ||

[[File:System Workflow.png|left|thumb]] | [[File:System Workflow.png|left|thumb]] | ||

| − | + | To find out more about Project Drab, contact [[Peter.yoon@canada.ca|Peter Yoon]] at the [[ROEB Transformation Office|Transformation Office]]. | |

| − | |||

| − | To find out more about Project Drab, contact [[Peter.yoon@canada.ca|Peter Yoon]] at the Transformation Office. | ||

Back to [[ROEB-Digital Transformation|ROEB Digital Transformation]] | Back to [[ROEB-Digital Transformation|ROEB Digital Transformation]] | ||

Latest revision as of 13:46, 13 April 2022

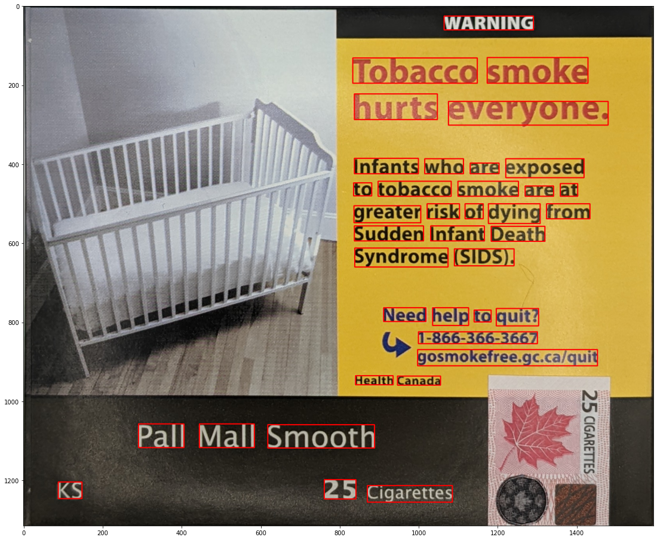

Project Drab is looking to improve the efficiency, reliability and consistency of the inspection process that is developed to check requirements driven from the Tobacco Products Regulations (Plain and Standardized Appearance) (“TPR (PSA)”) and the Tobacco Products Labelling Regulations (“TPLR”) under the Tobacco and Vaping Products Act (“TVPA”). Such regulations aim to:

· protect young persons and others from inducements to use tobacco products and the consequent dependence on them,

· prevent the public from being deceived or misled with respect to the health hazards of using tobacco products; and

· enhance public awareness of the health hazards of using tobacco products.

Health Canada inspectors currently use calipers to measure cigarette packages. These measurements are time consuming. For example, one such requirement is, “the placement of the tobacco brand name must be parallel to and in the same direction as the Health Warning Message and centered in the remaining space”. It takes at least 3 hours (180 minutes) to inspect a single package for the full set of the respective regulations. HC would like a tool to triage cigarette package compliance, focusing inspector time on confirming non-compliances, and allowing for more assessments over the period of a year.

The main objectives are:

- Reduce the time required to inspect a tobacco package from 180 minutes to less than 10 minutes, plus the time required to confirm the subset of requirements found to be Non-Compliant.

- Support keeping average precision if measurements within 0.5 mm.

- The number of assessments performed by HC (at office) per year is estimated at 200, which is used to quantify the expected benefit of having a computer-assisted assessment process. With a potential saving of 170 minutes per assessment, and should the assumptions b true, the total time saved amounts to ~567 hours per year.

- Adopting a computer-assisted assessment process that allows HC to conduct field assessments, which may not be as detailed as a full assessment done at office, yet can be seen as a benefit to HC

Potential / Proposed System Workflow

To find out more about Project Drab, contact Peter Yoon at the Transformation Office.

Back to ROEB Digital Transformation